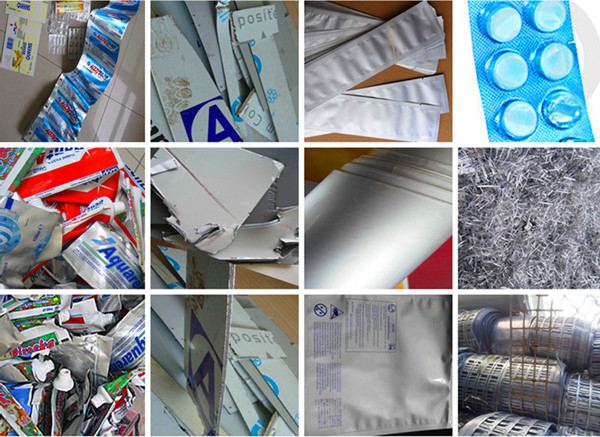

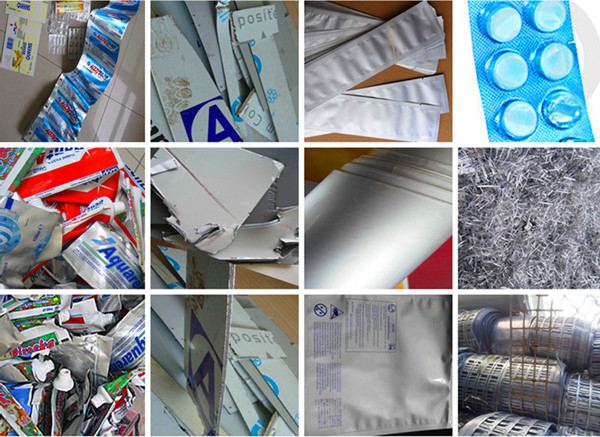

Aluminum Plastic Separation Plant can process all kinds of aluminum plastic materials, such as medical blister pack scraps, Aluminum Composite Panel,aluminum-plastic edge strip, aluminum-plastic shavings,aluminum-plastic capacitor material, toothpaste tubes, food packaings, aluminum foils, etc.

It adopt dry electrostatic separation.The separating purity is 99% above.

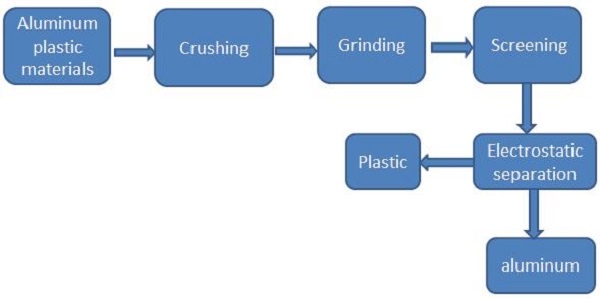

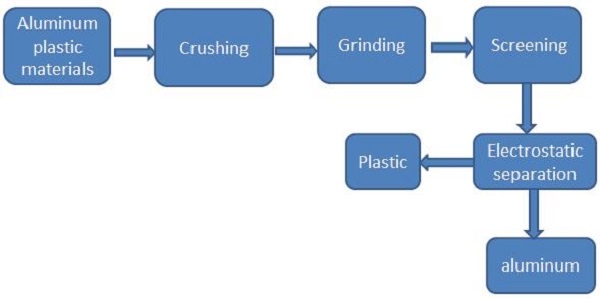

How to work for Aluminum Plastic Separation Plant

How to work for Aluminum Plastic Separation Plant

Aluminum-plastic separation and recycling equipment uses the physical crushing electrostatic separation method to separate the aluminum-plastic.

First, knife-cutting crusher crush Aluminum-plastic materials into pieces about 10 mm or less.

Then high-speed water-cooled turbine mill grind small Aluminum-plastic materials pieces into mixture of alu- plastic.

Nextly,mixture of aluminum and plastic is filtered by a vibrating screen to meet the requirements,while The unqualified materials are returned to the mill to continue crushing.

Finally,electrostatic separator separate aluminum and plastic.

For the whole process, The loss of aluminum and plastic is very low, and the recycling rate of aluminum is close to 99%. The equipment adopts completely dry physical separation, does not cause secondary environmental pollution, So it has good social and economic benefits.

Technical data:

For best offer,call us or whatsapp: +86 18738158809

Email: dahlia@dahliamachine.com

Website: https://dahliamachine.com

Technical data:

| Model | Power(kw) | Output(kg/ hour) | Dimension(mm) | Weight(kg) |

| LS-200 | 67 | 100-200 | 5200*5100*4200 | 5600 |

| LS-300 | 77 | 300-400 | 7500*6000*4200 | 6500 |

| LS-600 | 115 | 500-600 | 9500*7500*4200 | 7800 |

| LS-800 | 215 | 700-800 | 11500*8000*4200 | 12800 |

For best offer,call us or whatsapp: +86 18738158809

Email: dahlia@dahliamachine.com

Website: https://dahliamachine.com