Introduction:

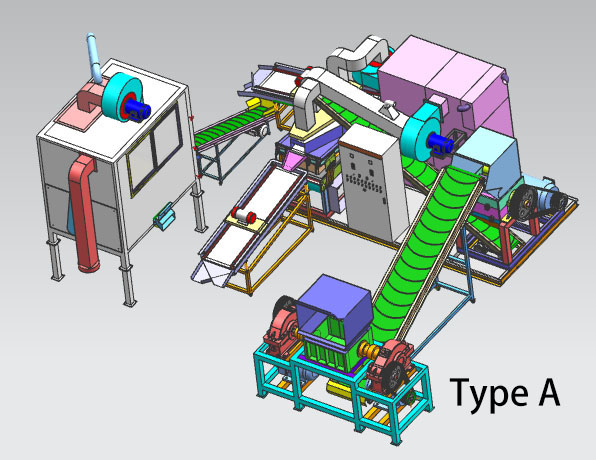

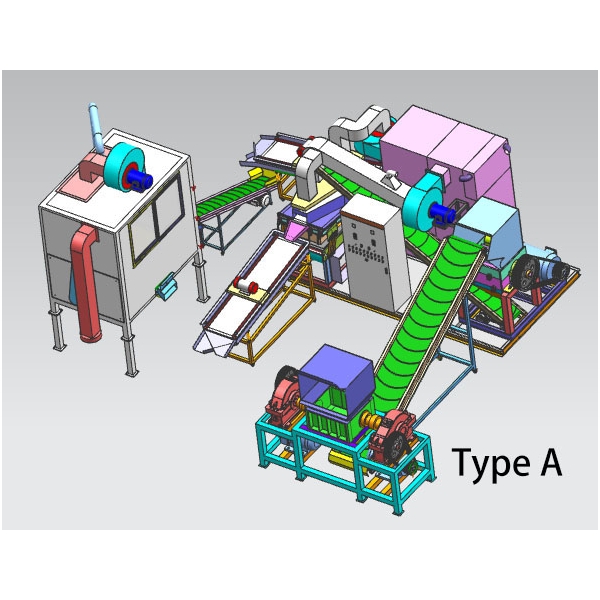

Automatic Cable Recycling plant can shredd and separate Any size copper cable or aluminum wire,High metal purity rate and efficiency.

After rough shredding, iron removal, fine crushing,gravity sorting and , electrostatic sorting process,it can arrive double recycling of plastics and metals and comprehensive utilization by complete dry physical separation.

Working process:

Automatic Cable Recycling plant can shredd and separate Any size copper cable or aluminum wire,High metal purity rate and efficiency.

After rough shredding, iron removal, fine crushing,gravity sorting and , electrostatic sorting process,it can arrive double recycling of plastics and metals and comprehensive utilization by complete dry physical separation.

Working process:

Pre-shredder---shred cable into manageable size and liberates steel from cable

Conveyor belt- transport cable piece into crusher

Overbelt magnet---remove the steel from cable pieces

Crusher-- crush cable pieces into fine unifirm sized partical, and liberates copper or aluminum from plastic to be sorted

Air separation---separate plastic from copper according to density.

Electrostatic separation--separate copper of plasttic, because plastic from air separation may container 2%--5% copper.

Electrostatic separation--separate copper of plasttic, because plastic from air separation may container 2%--5% copper.

Control panel--- control the whole system working