Advertising cloth recycling machine

one plastic fiber recycling machine. It can be used to crush and separate the plastic and fabric fibers from artificial leather, and advertising leather.

Advertising fabric recycling machine is one plastic fiber recycling machine.

It can be used for Crushing and separation of plastics and fiber composites.

How to work

Our plastic fiber recycling system transforms mixed waste materials—such as advertising banners, artificial leather, rain boots, and plastic pipes—into high-value plastic pellets and fiber, enabling sustainable resource reuse. Here’s how it works:

Step 1: Heavy-Duty Crushing for Uniform Particle Size

First, feed composite waste materials into our industrial-grade crusher. Equipped with robust blades and a high-torque motor, the crusher efficiently grinds or shears materials into consistent small particles (typically 6–10mm), homogenizing plastic, fiber, and other components into a mixed stream. This critical preprocessing step ensures optimal separation in subsequent stages.

Step 2: Gravity-Driven Separation via Centrifugal Force

The crushed mixture is then conveyed to the separator—via belt or screw conveyor—where advanced gravity separation technology takes over. Leveraging the differing specific gravities of plastic (denser) and chemical fiber (lighter), the separator’s precision-engineered crushing chamber, fitted with specialized blades and toothed plates, further loosens and isolates fibers from plastic.

As the mixture processes, dual-side centrifugal fans generate powerful airflow, suctioning lightweight fibers through dedicated outlets. Meanwhile, denser plastic particles, unaffected by the airflow, settle and exit through the lower discharge port, achieving near-complete separation of plastic and fiber.

Step 3: High-Quality Outputs for Versatile Reuse

The end result: purified plastic particles and clean fiber, each ready for value-added recycling. Plastic particles can be directly fed into granulation lines to produce recycled pellets (ideal for injection molding, extrusion, or 3D printing) or used as raw material for new plastic products (e.g., pipes, containers, or construction materials). Fibers, meanwhile, find applications in non-woven fabrics, insulation, or composite fillers, closing the loop on waste and reducing reliance on virgin resources.

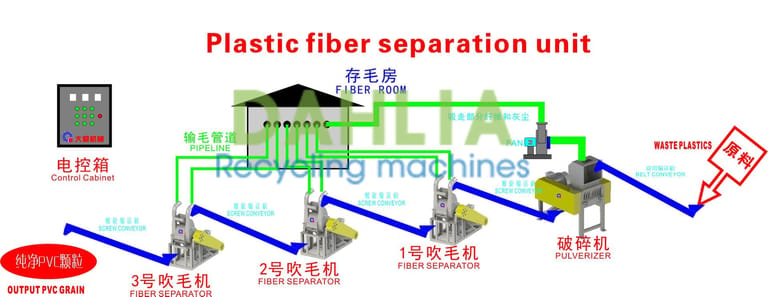

The diagram below shows the main components of a complete blower system:

Separating materials such as artificial leather and advertising fabric generally requires a crusher, three separators, and multiple conveyors, arranged according to the mesh size of the units. The first unit separates 60%, the second unit reaches 80%, and the third unit achieves complete separation. Depending on the plastic, the mesh size can be selected from 2.5 to 12 mm to achieve the desired effect.

Contact us

Whatsapp/Mobile: +86 187 3815 8809

© 2025. All rights reserved.