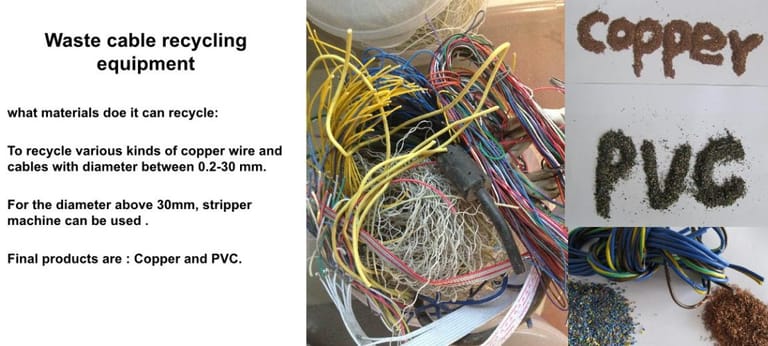

Scrap cable crusher separator machine for copper

High-quality copper granules and plastic granules scrap for recycling Scrap cable

Introduction:

Scrap cable crusher separator machine for copper can be used to separate High-quality copper granules and plastic granules scrap for recycling Scrap cable

How to work:

Recycling of Scrap cable wire involves a systematic, multi-step process designed to maximize metal recovery while ensuring environmental sustainability:

Step 1: Initial Crushing & Iron Removal

Scrap cable is first subjected to rough crushing to break down bulk materials. During this stage, iron-containing impurities are extracted using magnetic separation, ensuring the feedstock is free from ferrous contaminants that could hinder subsequent processing.

Step 2: Fine Crushing & Homogenization

The de-ironed material undergoes secondary crushing to produce a uniform mixture of metal (copper) and plastic. This step ensures particle size consistency, a critical factor for efficient separation in downstream processes.

Step 3: Gravity Separation

Leveraging the significant density difference between copper(metal) and plastic, the homogeneous mixture is processed through a gravity separator. This technology efficiently segregates the two components, with copper settling out due to its higher weight, while plastic particles are separated as lighter fractions.

Step 4: Electrostatic Refining

While gravity separation removes most plastic, residual copper fines or filaments (typically 2–5% of the plastic fraction) may remain. An electrostatic separator is employed to recover these minute copper particles. By utilizing differences in electrical conductivity, copper—being conductive—is separated from non-conductive plastic, ensuring near-complete metal retrieval.

The result is a high-purity copper product and plastic fraction free of metallic residues, significantly enhancing the value of both recycled materials.

Raw materials and final products:

Related products:

Small cable recycling machine for small recycling center

Contact us

Whatsapp/Mobile: +86 187 3815 8809

© 2025. All rights reserved.